Why Trench Safety Matters in Bangladesh

Across Bangladesh’s rapidly expanding construction zones from Dhaka’s utility corridors to Chattogram’s drainage upgrades trench work saves time but hides one of the deadliest threats to rescuers: collapse. Each year, multiple responders and laborers are buried within seconds because of unshored or poorly stabilized excavations.

According to DGFSCD incident data (2024), most collapses occur in soils saturated by monsoon rain or leaking pipes. The danger isn’t only to the trapped worker secondary collapse during rescue remains the leading killer of responders.

This guide combines Bangladesh Fire Service & Civil Defence (DGFSCD) protocols with OSHA 1926 Subpart P and NFPA 1670/1006 standards to provide a step-by-step, field-ready method for trench paneling and shield setup tailored to local soil and equipment realities.

Understanding Trench Hazards in Bangladesh

1. Common Causes of Collapse

- Water infiltration: Continuous rainfall or drainage seepage weakens trench walls.

- Poor soil classification: Most regions feature clay-loam or silty soil (Type C under OSHA) least stable without support.

- Improper spoil placement: Excavated soil piles placed less than 0.6 m from the lip overload the wall.

- Vibration: Passing traffic or machinery triggers micro-cracks that expand into full collapse.

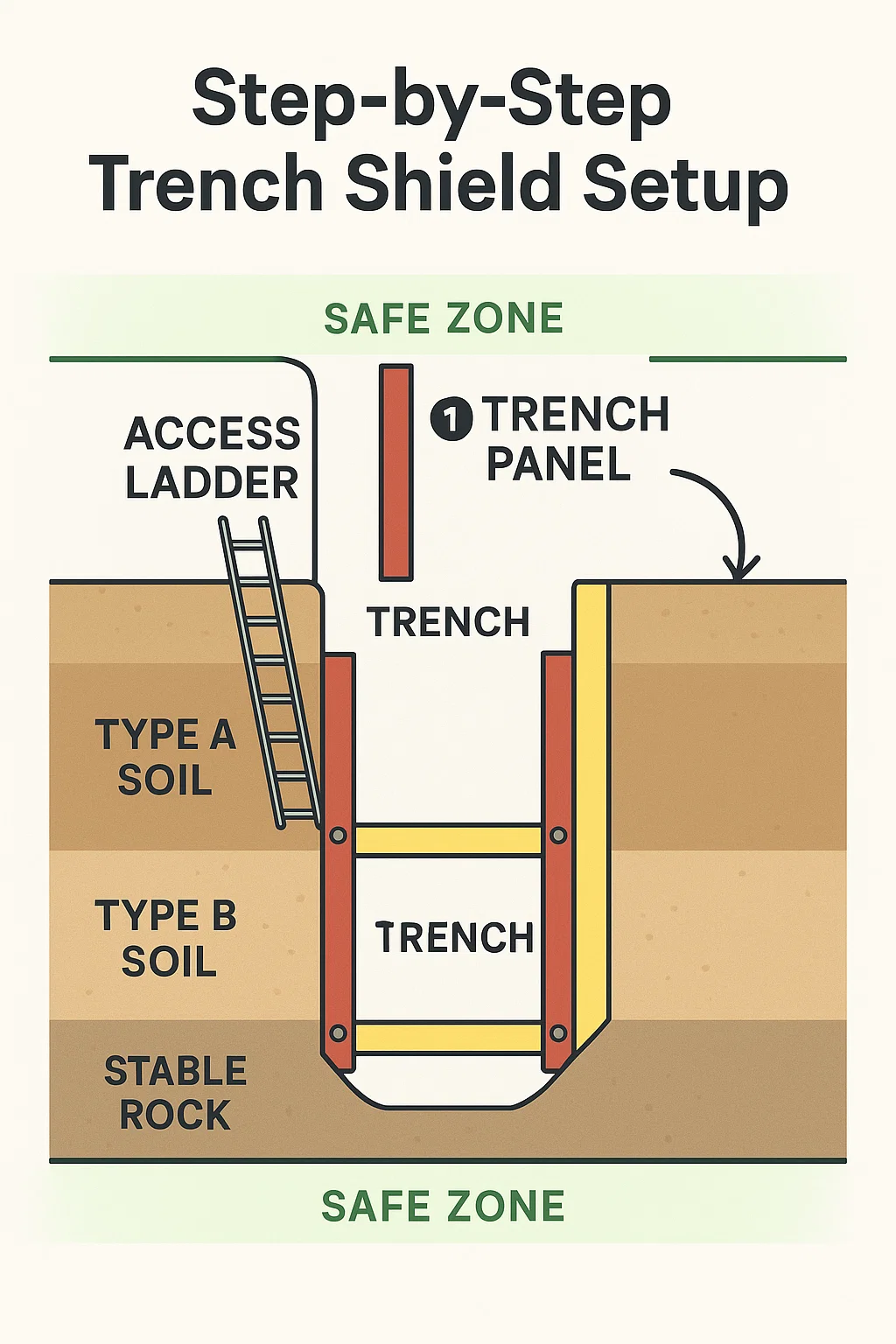

2. Soil and Depth Classification (DGFSCD Table 1)

| Soil Type | Local Example | Typical Stability | Max Unsupported Depth |

|---|---|---|---|

| Type A – Cohesive clay | North Rajshahi | Very stable (dry) | 1.2 m |

| Type B – Loam / sandy clay | Dhaka–Gazipur | Moderate | 0.9 m |

| Type C – Saturated or layered soil | Coastal & flood zones | Unstable | 0.6 m or less |

Pro Tip #1 – Never Guess Soil Type:

If the trench floor feels soft or the walls glisten with moisture, treat it as Type C the most dangerous.

Equipment and Paneling Systems Used by DGFSCD

DGFSCD field units commonly employ modular trench panels fabricated from steel or high-density aluminum with hydraulic struts for adjustability. Imported kits from India or China are supplemented by locally welded panels designed by the Fire Service mechanical workshop.

Standard Equipment Checklist

| Equipment | Specification | Purpose |

|---|---|---|

| Trench panels | 1.2 × 2.4 m, 6–8 mm steel | Side-wall support |

| Trench shields (box type) | Up to 3 m long, 1.5 m high | Full-wall protection |

| Hydraulic shores | 30–70 kN capacity | Lateral pressure balance |

| Timber whalers / struts | 100 × 100 mm hardwood | Supplement or anchor |

| Ladders | Extending 1 m above lip | Safe access/egress |

| Air monitor | Combustible & O₂ sensors | Atmospheric safety |

| PPE | Helmet, gloves, SCBA (if gas) | Rescuer protection |

Pre-Entry Hazard Assessment

Before anyone enters the trench, DGFSCD protocol demands a three-phase safety review:

Phase 1 – Scene Size-Up

- Secure perimeter (minimum 1.5 × depth).

- Stop nearby machinery or water inflow.

- Identify utilities using local maps or site engineer brief.

Phase 2 – Soil & Atmospheric Testing

- Use a penetrometer or visual classification.

- Conduct gas and O₂ tests at bottom, middle, and top levels.

- Document readings per DGFSCD Form TR-01.

Phase 3 – Stabilization Readiness

- Assign a Safety Officer (DGFSCD Level II Rescue certified).

- Check panel and shore condition no rust, deformation, or oil leaks.

- Prepare backup air supply and medical standby.

Pro Tip #2 – No One Enters Until Shield Installed:

Entry before shoring violates both OSHA 1926.652(a) and DGFSCD Rule 4.3. It’s the difference between a rescue and a recovery.

Step-by-Step Trench Paneling Procedure

Step 1: Establish Safe Access

- Place ladder on firm ground; extend 1 m above trench lip.

- Maintain 45° angle, tied to secure anchor.

Step 2: Set Trench Dimensions

- Measure width (typically 1.0–1.2 m for single-person access).

- Inspect bottom for seepage; pump out standing water.

Step 3: Lower the First Panel

- Using a backhoe or manual rope system, lower the first panel vertically along one wall.

- Keep rescuers outside the trench until the panel is stable.

Step 4: Install Second Panel and Hydraulic Shores

- Place the opposite panel; align top edges.

- Insert hydraulic shores at top, mid, and bottom levels.

- Apply pressure gradually until panel surfaces contact soil.

| Shore Level | Typical Spacing (Type C Soil) |

|---|---|

| Top | 0.6 m below lip |

| Middle | Mid-height |

| Bottom | 0.3 m above trench floor |

Step 5: Check Alignment and Pressure

- Use spirit level and gauge to ensure even load.

- Over-pressurization can bend panels maintain ≤ 60 kPa.

Step 6: Install End Protection or Shield Box

- If trench length exceeds 3 m, use end panels or a full shield box to prevent shear-end collapse.

Step 7: Entry & Victim Operations

- Only the Rescue Team Leader authorizes entry.

- Maintain continuous voice contact.

- Use tripod and lifeline if trench > 1.5 m deep.

Step 8: Removal Sequence

- Remove personnel first, then release hydraulic pressure from bottom up.

- Panels are extracted using lifting hooks or crane line.

Pro Tip #3 – Shore As You Go:

Never expose more than 1 m of unshored wall. Move panels and shores progressively with team coordination.

DGFSCD Operational Coordination

Chain of Command (ICS Model)

- Incident Commander – typically Station Officer (ICS Level I)

- Rescue Operations Officer – manages trench entry and shoring

- Safety Officer – ensures compliance and gas monitoring

- Medical Unit Leader – EMT/Paramedic for casualty care

- Logistics Officer – tools, lighting, and pump operations

Communication Protocol

- Hand signals and radio codes standardized under DGFSCD Form ICS-205.

- Use phrase “All Stop” to halt entry if any movement or cracking is observed.

Medical Integration

- EMTs stage 3–5 m from trench edge, providing IV, airway, or spinal support before extraction.

- Cooling and oxygenation are prioritized due to Bangladesh’s humid climate.

Case Study – Trench Collapse, Narayanganj 2023

In 2023, a sewer-line trench (2.5 m deep, 1 m wide) collapsed after a night storm. Two workers were trapped. DGFSCD Rescue Unit 7 deployed within 15 minutes.

- Problem: Type C soil, high moisture, no shoring installed.

- Action: Rescuers installed modular steel panels with three hydraulic shores before entry.

- Outcome: Both victims extricated alive after 45 minutes; zero secondary collapse.

Key Lesson: Rapid deployment of pre-assembled panel kits reduced exposure time. Regular drills now include night-operation readiness and water-pumping coordination.

Post-Rescue Procedures

- Debrief and Documentation

- Complete DGFSCD Form TR-09 within 2 hours.

- Record soil type, tools, personnel, and time in-trench.

- Equipment Cleaning

- Wash panels with mild detergent; dry to prevent corrosion.

- Inspect hydraulic hoses for leaks.

- Psychological Check-In

- Encourage team debriefing; trench rescues are high-stress events.

- Community Education

- DGFSCD outreach teams conduct safety sessions for local contractors on trench depth limits and spoil management.

Common Mistakes and How to Avoid Them

| Mistake | Consequence | Prevention |

|---|---|---|

| Entering before shoring | Secondary collapse, fatality | Install panels first |

| Using damaged panels | Structural failure | Inspect before deployment |

| Ignoring water inflow | Undermines walls | Pump continuously |

| Insufficient ladder access | Delayed egress | Maintain ≤ 7 m spacing |

| Over-pressurizing shores | Panel deformation | Monitor gauges |

Pro Tip #4 – Train With What You’ll Use:

Local DGFSCD units often rely on modified panels. Train with the same gear you’ll deploy, not idealized imported kits.

Training and Simulation

DGFSCD’s National Rescue Training Center in Mirpur now includes a Trench Rescue Simulator built from reinforced pits and adjustable soil trays. Trainees practice:

- Soil classification

- Panel placement under time constraint

- Victim stabilization using spine boards

- Multi-agency coordination drills

Training Frequency: At least one refresher every six months per NFPA 1006 §8.2.

PPE and Environmental Control Table

| PPE Item | Standard | Bangladesh Adaptation |

|---|---|---|

| Helmet | EN 397 / DGFSCD Spec R-4 | Chin strap for monsoon winds |

| Gloves | EN 388 | Waterproof coating |

| Boots | Steel-toe, puncture-proof | Non-slip sole for clay |

| Respiratory protection | NIOSH N95 or SCBA | Use SCBA in gas detection > 10 ppm |

| Cooling gear | N/A | Cotton underlayer for humidity |

Integrated Safety Checklist (DGFSCD Form TR-Pre-Ops)

Before Entry:

☑ Scene cordoned and utilities marked

☑ Soil type classified (A/B/C)

☑ Atmospheric test complete

☑ Panels inspected and positioned

☑ Ladders in place within 7 m intervals

☑ Backup rescue plan and medic ready

During Operation:

☑ Constant visual watch on wall movement

☑ Shores checked every 15 min

☑ Communication maintained

☑ Spoil kept ≥ 0.6 m from edge

After Operation:

☑ Personnel accounted for (PAR)

☑ Tools cleaned and logged

☑ Site released to authority

Table – Recommended Panel & Shield Configuration by Depth

| Trench Depth | Panel Height | No. of Shores | Shield Requirement |

|---|---|---|---|

| ≤ 1.2 m | 1.2 m | 2 | Not mandatory |

| 1.2–2.4 m | 2.4 m | 3 | Optional (Type B) |

| 2.4–3.6 m | 3.0 m | 3–4 | Required |

| 3.6–4.5 m | 3.0 m | 4 | Mandatory twin shield |

Weather and Environmental Considerations

- Monsoon Season (Jun–Sep): Increase shore pressure 10–15 % to counter wet soil loads.

- Heat and Humidity: Implement 15-min cool-down rotations every hour.

- Night Operations: Use waterproof LED lighting; ensure generator placed > 10 m from trench.

Integrating Community Contractors

DGFSCD emphasizes partnership with local construction firms. Rescue officers conduct Toolbox Talks outlining:

- Minimum shoring for any excavation > 1.2 m deep

- Spoil distance and access ladder standards

- Emergency call procedures (999 / DGFSCD hotline)

This outreach has cut urban trench emergencies by ~25 % since 2022.

Maintenance and Inspection

Every panel and shield must pass a six-month inspection cycle:

| Inspection Item | Standard | Interval |

|---|---|---|

| Weld joints | Visual, ultrasonic | 6 months |

| Hydraulic seals | Pressure test @ 60 kPa | 3 months |

| Strut pins | Wear ≤ 1 mm | 6 months |

| Ladder rails | Integrity test | 12 months |

Defective gear is tagged OUT OF SERVICE until certified by DGFSCD Mechanical Division.

Future Innovations

- Composite Panels: Lighter fiberglass panels under pilot testing with BUET mechanical engineers.

- IoT Pressure Sensors: Real-time load monitoring planned for 2026 DGFSCD modernization program.

- Drone Recon: Thermal imaging to detect voids before entry.

These technologies will enhance safety and align Bangladesh’s trench-rescue capability with global best practice.

Building a Culture of Safe Excavation

Every trench rescue in Bangladesh tests a responder’s judgment more than strength. The simple act of refusing to enter an unshored pit embodies the discipline DGFSCD champions. By applying structured paneling and shield procedures, responders turn chaos into controlled precision saving lives while ensuring their own.

As infrastructure expands, training, inspection, and strict adherence to DGFSCD, OSHA, and NFPA standards will define success. Each properly placed panel isn’t just metal in the ground it’s a promise that everyone goes home.

Jordan Hayes, a rescue professional with years of hands-on experience, shares expert insights and tips to enhance safety and preparedness on arescuers.com