OBJECTIVES

Upon completion of this lesson, you will become familiar with:

- Define the Rope and describe the parts of a rope

- List the Types of Rope

- Describe the Care and Maintenance of Ropes

- Describe the Inspection of Ropes

- escue Knots

1. Ropes

A rope is the one essential element in the high-angle system.

- It is in essence a tool.

- As with all tools, the correct rope should be chosen to fit the job

Rope is a tool that is used in emergency situations to save human lives.

A length of thick strong cord made by twisting together strands of Hemp, Sisal, Nylon or similar material.

Rope is a multi purpose tool used from ancient time. Ropes are essentially required to lower, lift and pull victim or any load in any emergency situation.

1.1 Parts of a Rope (According to use)

- Working End: Part of the rope which is tied with the anchor point is called working end.

…………………………………………………………………………………….

- Running End: Part of the rope which is used for working such as hoisting.

…………………………………………………………………………………….

- Standing Part: Part of the rope between the working end and the running end.

…………………………………………………………………………………….

1.2 Rope Construction

The choice of a rope for a specific job depends not only on the fiber from which the rope is made but also on the manner in which the rope is constructed.

- Laid

- Plaited

- Braided

- Kernmantle

1. LAID

- Also known as twisted or hawser lay

- Small fiber bundles of material are twisted and then combined in larger bundles, usually in groups of three, which are twisted around one another in the opposite direction.

- Laid rope:

i. Adds a great amount of spin during a rappel

ii. Tends to be very stretchy

iii. Is susceptible to damage from abrasion

- Ropes of laid construction have been displaced in most high-angle work by other designs.

2. PLAITED

- Usually consists of bundles of fibers plaited together

- Tend to be soft and pliable

- Prone to picking (snagging and pulling out of fiber bundles)

3. BRAIDED

- Hollow-braid rope

– Essentially a very thick sheath

– Sometimes has a filler, such as scrap yarn or filament plastic

– Typically found in inexpensive hardware store

–type rope, not in life safety line

- Essentially a rope constructed of a solid braid covered with a hollow braid

- One braid acts as the rope core.

- The second braid is constructed around it to:

– Act as a sheath

– Help protect the inner braid

4. KERNMANTLE

- Kern means “core”

- Mantle means “sheath” or “cover”

- The kernmantle rope design consists of a central core of fibers that is covered by a woven sheath.

- Kernmantle construction produces a rope that is strong and resists damage but is easy to handle.

Kern: It is the internal fiber of the rope and 70% strength depends upon this part.

Mantle: It is the outer covering of the rope. It protects the kern and 30% strength of rope is due to this.

2. Types of Rope

2.1 Utility Rope

2.2 Life Safety Rope

2.1 Utility Rope

This rope is made of natural fibers and cannot be used in life saving activities. It is used to secure the equipments. It is made by connecting several fibers (Unlike a single fiber throughout the rope which enhances strength of rope i.e. Polypropylene, Polyester and Polyethylene Material) so its strength is in doubt. Water and other chemicals may damage this type of rope. These are available in different materials i.e. Cotton, Manilla, Jute, sisal and all natural fibers. These ropes are sensitive to temperature.

2.2 Life Safety Rope

Rope intended to support people during rescue, fire fighting, other emergency operation, or during training. Different companies make ropes in various diameters i.e. 8, 9, 10, 11, 12mm etc.

Life safety rope is divided into two types.

2.2.1 Static Rope

2.2.2 Dynamic Rope

2.2.1 Static Rope (Low-stretch)

A type of rope designed to be used in applications such as rescue, rappelling and ascending in which high or moderate stretch would be a disadvantage and in which no falls, or only short falls, are expected before the rope catches the climber.

A static rope is one designed with low elongation characteristics. These ropes normally elongate around 2% to 3% under one person body weight, and not more than 20% at ultimate breaking point.

2.2.2 Dynamic Rope (high-stretch)

A type of rope designed for high stretch to reduce the shock on the climber and anchor system. This type of rope usually is used in Rock climbing and mountaineering. It is also called as High Stretch rope. The two other characteristics of dynamic ropes are Softness and Pliability. Some dynamic climbing ropes may elongate by 60% before breaking.

Rope Fiber Comparison Chart

| Fiber Type | Strength | Stretch | UV Resistance | S.G* | Melt Point | Cost |

| Nylon | High | High | Good | 1.14 | 219-254°C | Moderate |

| Polyester | High | Low | Good | 1.38 | 256°C | Moderate |

| Polypropylene | Low | Low | Poor | 0.91 | 170°C | Very Low |

| Polyethylene | Low | Low | Poor | 0.93 | 135°C | Very Low |

| Aramids | Very High | Very Low | Fair | 1.44 | 500°C** | Very High |

| HMPE | Very High | Very Low | Fair | 0.96 | 135°C | Very High |

| LCAP | Very High | Very Low | Fair | 1.41 | 330°C | Very High |

*Specific Gravity

** Aramids decompose rather than melts

HMPE= High Modulus Polyethylene Fibers

LCAP= Liquid Crystal Aromatic Polyester Fiber

2.3 Rope Colors

Color can serve a functional purpose:

- If several ropes are used together, the different colors can help distinguish one line from another.

- You can buy a different colored rope for each year, making it easier to identify the age of the rope.

- Varying colors can be used for different sizes of rope.

3. Care and Maintenance of Ropes

A rope’s performance, how long it lasts and its safety still depend on how well it is cared for. The condition of a rope ultimately depends on its history, the age of rope, condition and care received.

3.1 Care of ropes BEFORE USE

- Remove the kinks in rope

- Secure the end of ropes with stopper.

- Inspect the rope thoroughly.

- Do not use if there is any damage.

3.2 Care of ropes DURING USE

- Do not drag on ground.

- Do not use on wet places.

- Do not pass over the sharp edges.

- Avoid contact of heat, grease, oil and chemical.

- Avoid walking or standing on the rope.

3.3 Care of ropes AFTER USE

- Inspect the rope thoroughly. If there is damage tie a knot there. Report immediately and do not use it again.

- Secure/ Fold/ Coil the rope after removing kinks.

- Do not leave knots in a rope as they can reduce its strength.

- Do not dry ropes in front of fire or other heat source.

- Store ropes in a safe place under covering, off the floor, preferably in racks in a place free from the extremes of temperature and out of contact with any contaminating materials, moisture, dust, rodents and sharp edges.

Store the rope in well ventilated dry place and avoid direct contact of sunlight, oil, grease etc.

3.4 How Ropes are Damaged

The ropes may be damaged during use. Some of the reasons are listed below:

- Contact of Harmful substances i.e. Chemicals

- Overloading a rope

- Damaging from falling objects i.e. Rocks or tools that fall on the rope, particularly when it is under load.

- Abrasion i.e. During Ascending, causing the rope to “SAW” back and forth across a rock or hard object.

4. Inspection of Ropes

All rescue ropes should be inspected before, during and after use. The inspection should be conducted by visual examining the rope, and by thoroughly touch the rope.

4.1 Visual Examination:

This includes the following:

- Discoloration of filaments: Any changes in the original color of the rope filaments could indicate contamination by chemicals.

- Melting: Any smooth areas could indicate the rope has been damaged by heat fusion.

- White filaments: Where the sheath has been damaged, the white core filaments may protrude through it.

- Size uniformity: The rope may have been damaged by mechanical impact or over stressing. This may be evidenced by a change in the obvious shape and diameter of the rope.

- Abrasion: The damaging wear on rope and other equipment caused by rubbing against abrasive material.

- Stiffness: Any inconsistency in the texture of the rope and its stiffness. A bight of rope should have uniform radius around the bend, and inconsistencies may be soft spots which indicate core damage.

4.2 Check by Feel (Touch): Every part of the rope should be passed through the bare hand, feeling for the following:

- Stiffened filaments: Possible over-loading or contamination.

- Changes in diameter: Depressed irregularities in the rope diameter (soft spots) may indicate core damage, while increases in the apparent diameter may be due to severe twisting of the core, or the protrusion of core filaments through the sheath.

- Contamination: Seek out dirt or other materials.

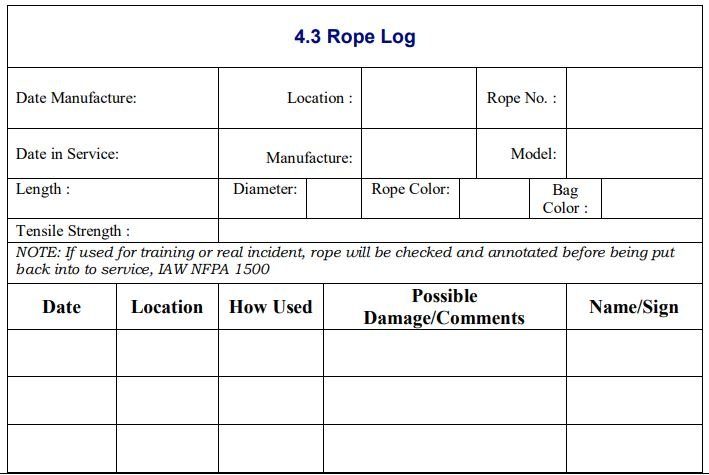

Damaged or defective ropes must be appropriately labeled and removed from service immediately and maintain Rope Log.

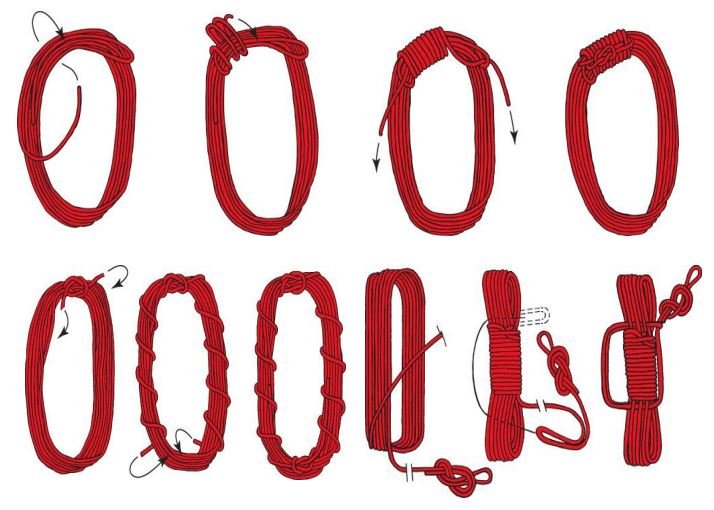

4.4 Coiling of Ropes

- Used for storing and transporting ropes before bagging became common practice

- The specific type of coil depends on the circumstances or environment in which the rope is to be used.

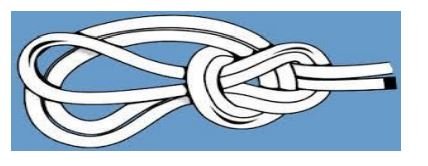

5. Rescue Knots

- Knot

An intertwined loop of rope, used to fasten two ropes to one another. - Hitch

A hitch is a knot that attaches a rope to any object. - Bight

Any curved section between the ends of the rope.

- Loop

A bight becomes a loop when ends of the rope are crossed.

- Bend

A class of knot that joins two ropes or webbing pieces.

Note:

Always dress the Knot and tie properly.

5.1 Stopper Knot

- This knot is applied on the ends of the rope to secure the fibers of the ropes.

- It is also applied after every knot to secure the knot.

…………………………………………………………………………………….

5.2 Clove Hitch

- Clove hitch is used to fasten the rope on anchor point.

- It has the advantage of being easy to tie and to adjust.

- When it is under load, it will have tighter grip on anchor point.

…………………………………………………………………………………….

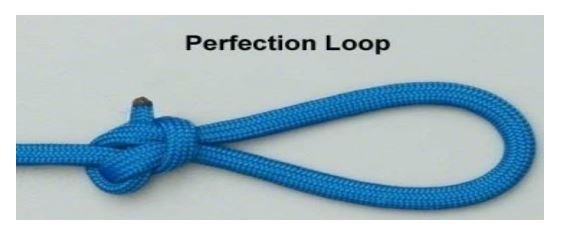

5.3 Reef Knot

- Reef knot is applied to join the ropes of same diameter.

…………………………………………………………………………………….

5.4 Slip Knot

- This knot is easily undone by pulling the tail.

- The slip knot is related to the running knot; which will release when the standing end is pulled.

…………………………………………………………………………………….

5.5 Sheet Bend

- This knot is used to join the ropes of different diameter.

…………………………………………………………………………………….

5.6 Figure of eight on bight

- It is also applied on anchor point. After the figure of eight is tied, the loop is used on anchor point.

…………………………………………………………………………………….

5.7 Round turn with two half hitches

- It is also used to tying a rope on anchor point.

- It has the advantages that it will not over-tighten, it is easy to adjust, and it imposes minimal stress on the rope.

…………………………………………………………………………………….

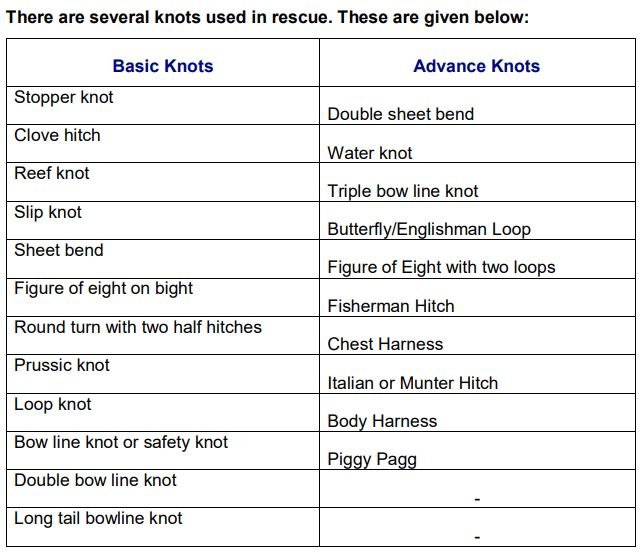

5.8 Prussic Knot

- This knot is very important knot.

- It works as lock in rope system.

- If something happens to rope; it holds the rope and gives advantage in securing the rope.

…………………………………………………………………………………….

5.9 Loop Knot

- This knot is used to make an anchoring hook; it is very simple knot and rapid to make and use.

…………………………………………………………………………………….

5.10 Bowline

- Bowline is also known as safety knot. Rescuers use this for personal safety and also to secure the victim.

…………………………………………………………………………………….

5.11 Double Bowline Knot

- This knot is used during water emergency for personal safety and also applies on anchor point.

…………………………………………………………………………………….

5.12 Triple Bowline Knot

- This knot is used to make the full body harness for victim.

…………………………………………………………………………………….

5.13 Long Tail Bowline Knot

- An interlocking Long tail bowline knot is used for lowering litters and for raising operations.

…………………………………………………………………………………….

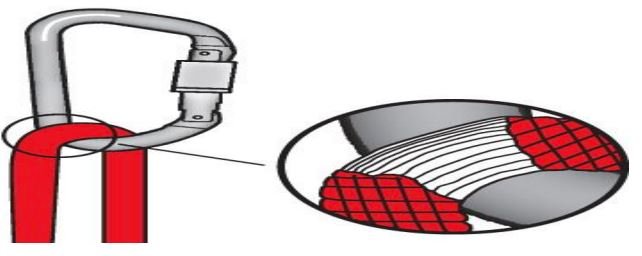

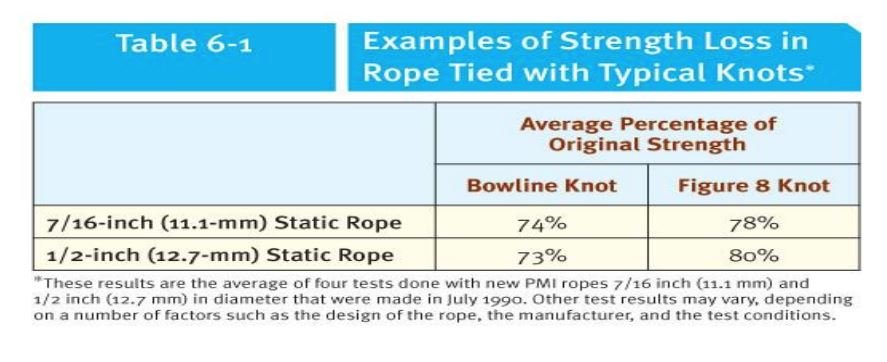

How Knots Affect Rope:

Every knot diminishes the strength of rope somewhat.

- The rope fibers on the outside of the bend carry most of the load on the rope.

- The fibers on the inside of the bend carry very little of the load or none at all.

- Some knots have sharper bends, resulting in greater strength loss in a rope than occurs with knots that have more open bends.

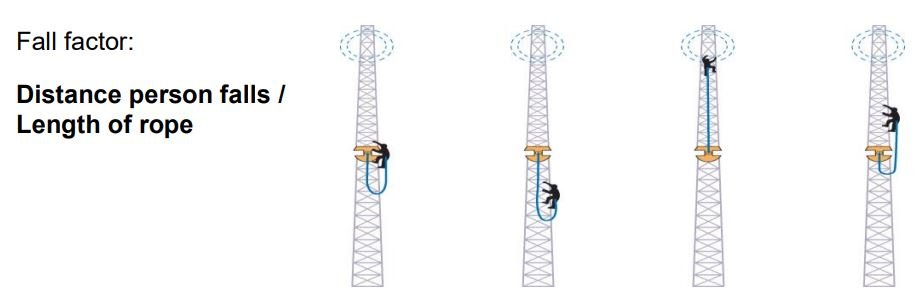

Fall Factor

The relationship between how far a person falls and the length of rope that is available to catch that fall.

Final Words

Ropes are essential tools in rescue operations, ensuring safety and efficiency in high-angle situations. Understanding rope types, construction, care, and proper inspection is crucial for effective use. Rescue knots play a vital role in securing loads, anchoring points, and ensuring stability during emergency operations.

Proper maintenance and handling of ropes extend their lifespan and enhance performance. Regular inspection and adherence to safety protocols prevent failures and accidents.

Mastering rope techniques and safety procedures is fundamental for rescuers. Always choose the right rope for the job, maintain it properly, and use correct knots to ensure reliable and secure operations.

Emma Lee, an expert in fire safety with years of firefighting and Rescuer experience, writes to educate on arescuer.com, sharing life-saving tips and insights.