What is Shoring and Its Methods?

Shoring is the temporary support of unstable or weakened structures, primarily used in structural collapse incidents, excavation zones, or natural disasters. The main purpose is to minimize the risk of further collapse while protecting both trapped victims and rescuers.

Shoring methods are categorized based on structural needs, such as vertical load-bearing, lateral support, or stabilization of openings.

Key characteristics of shoring:

Temporary

Load-bearing

Modular and adjustable

Must be installed quickly and safely

Why Shoring Matters in Rescue Operations

Proper use of shoring methods can make the difference between a safe extraction and a catastrophic secondary collapse. Urban search and rescue teams often encounter:

Pancaked floors

Leaning walls

Broken beams

Cracked masonry

By applying appropriate shoring techniques, responders reduce risk while ensuring safer victim access and tool operation zones.

Key Factors That Influence Shoring Method Selection

Every shoring scenario is unique. Your approach should be guided by a thorough scene size-up, considering the following:

| Factor | Description |

|---|---|

| Material Weight | Heavier structures require thicker lumber or steel shores |

| Structural Damage | The more unstable the structure, the more urgent and robust the shore |

| Foundation Stability | Loose soil may require base reinforcement |

| Load Direction | Vertical vs lateral loads dictate shore type |

| Available Equipment | Limited material calls for improvisation |

| Space Constraints | Narrow corridors vs open collapse zones |

| Access Needs | Some shores block egress, others allow entry |

Types of Shoring Methods Explained

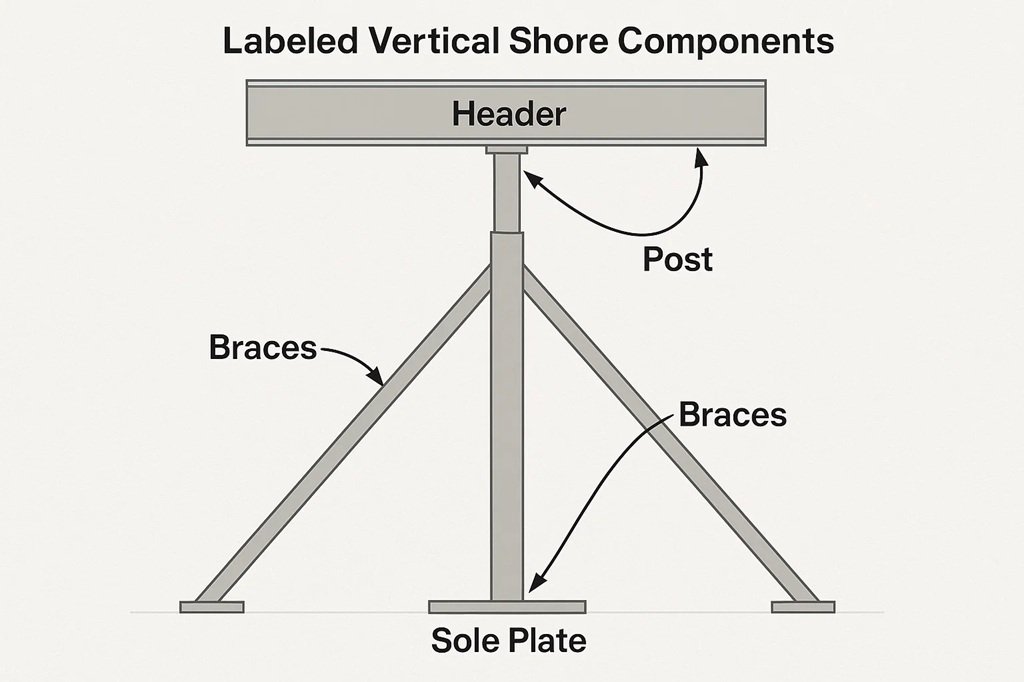

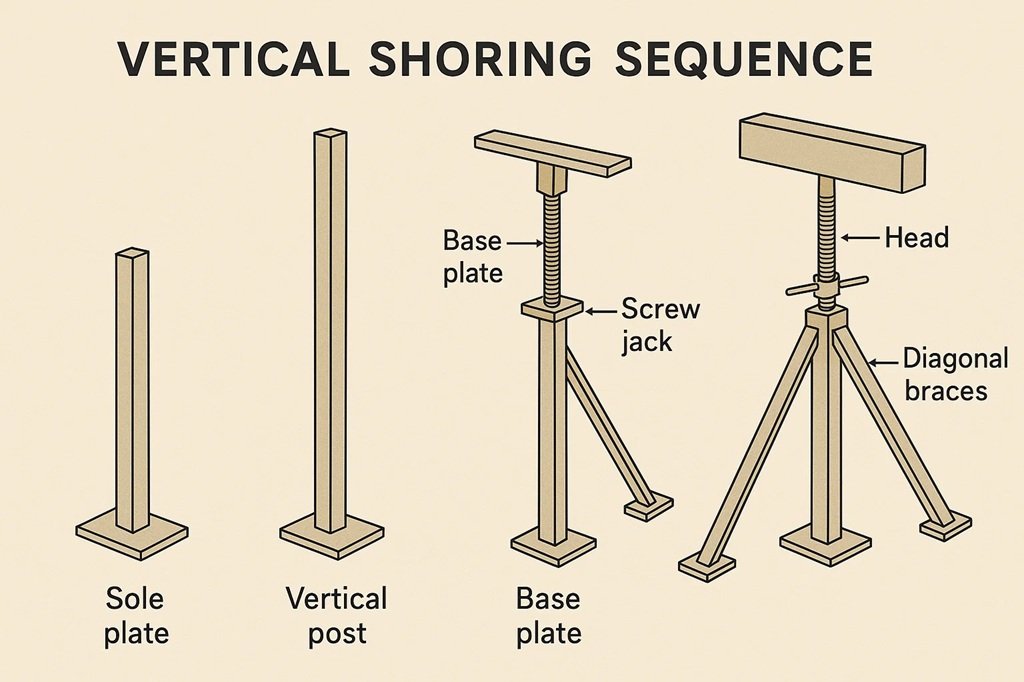

Vertical Shoring

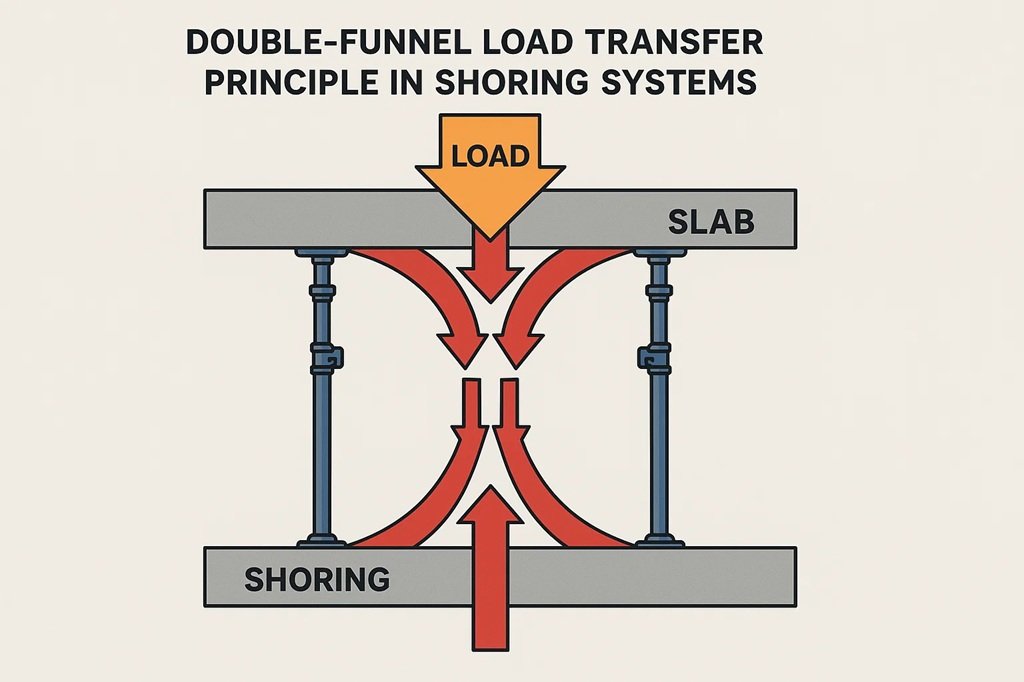

Vertical shores are designed to stabilize ceilings, floors, or roof structures. Typically built with timber or aluminum struts, they distribute the vertical load from above down to a solid foundation.

Use case: Replacing missing support walls, holding up sagging ceilings.

Window and Door Shore

These shores reinforce openings in damaged structures. While they maintain integrity, they also allow rescuers to enter and exit safely.

Best Practice: If the opening must remain accessible, do not install diagonal bracing.

T-Spot Shore

Used for quick stabilization, this shore is essential during initial victim extrication where time is critical.

Fast to construct

Minimal material needed

Short-term use only

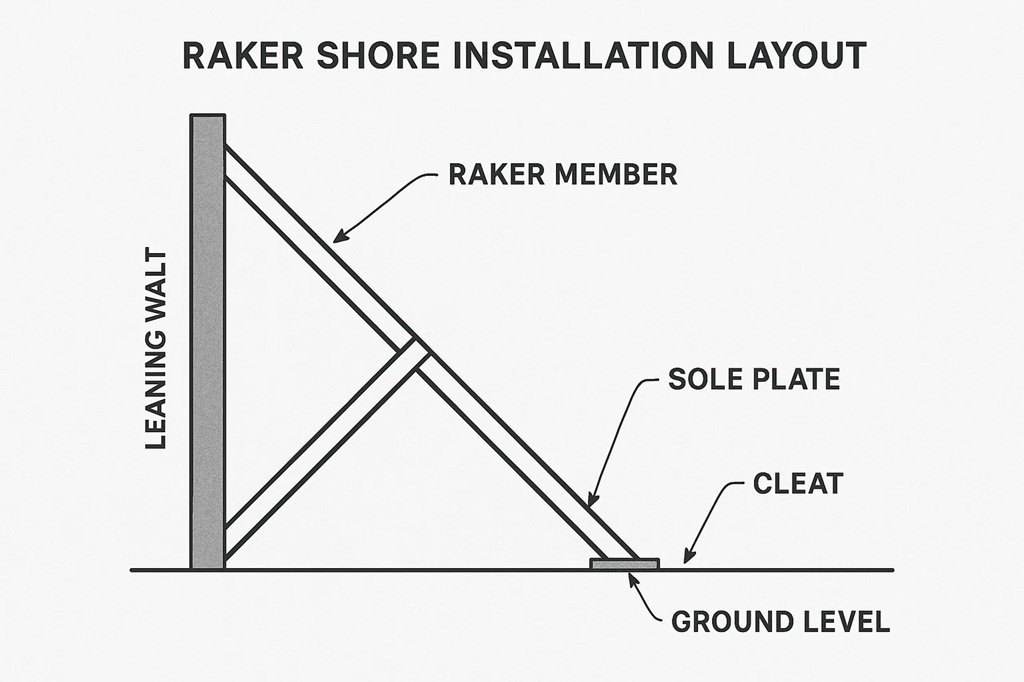

Raker Shore

Raker shores support leaning or bulging walls. Always constructed in pairs or series for maximum stability.

Triangular configuration

Uses sole plate, wall plate, and diagonal support

Laced Post Shore

This is a high-capacity support structure, typically used to hold sagging floors or overhead hazards.

Built with four vertical posts

Braced and laced for strength

Can serve as a safe zone during operations

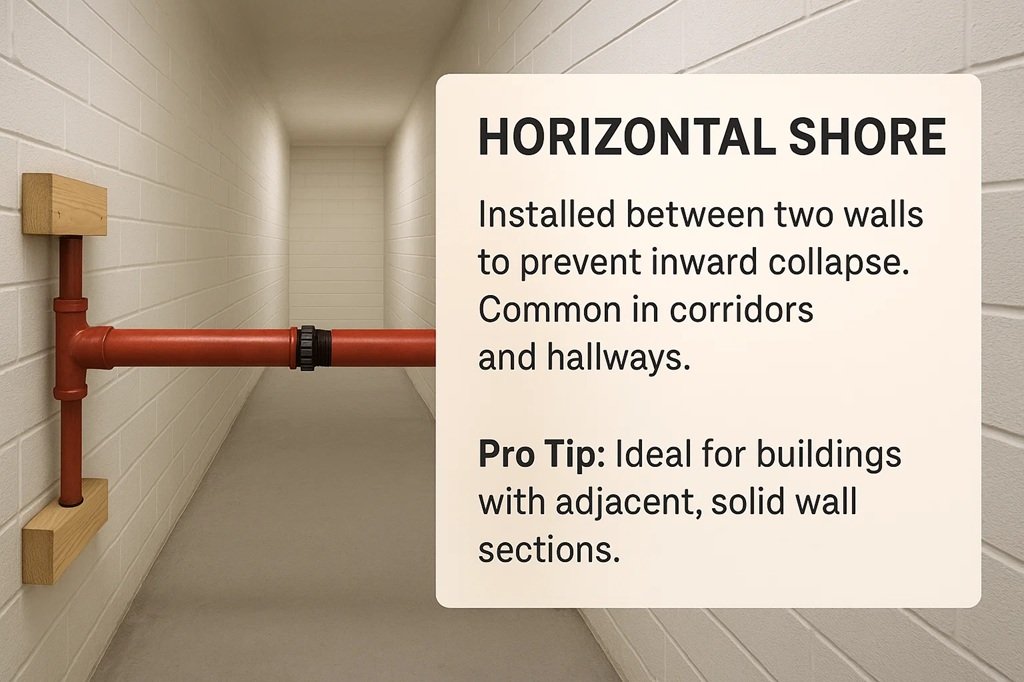

Horizontal Shore

Installed between two walls to prevent inward collapse. Common in corridors and hallways.

Pro Tip: Ideal for buildings with adjacent, solid wall sections.

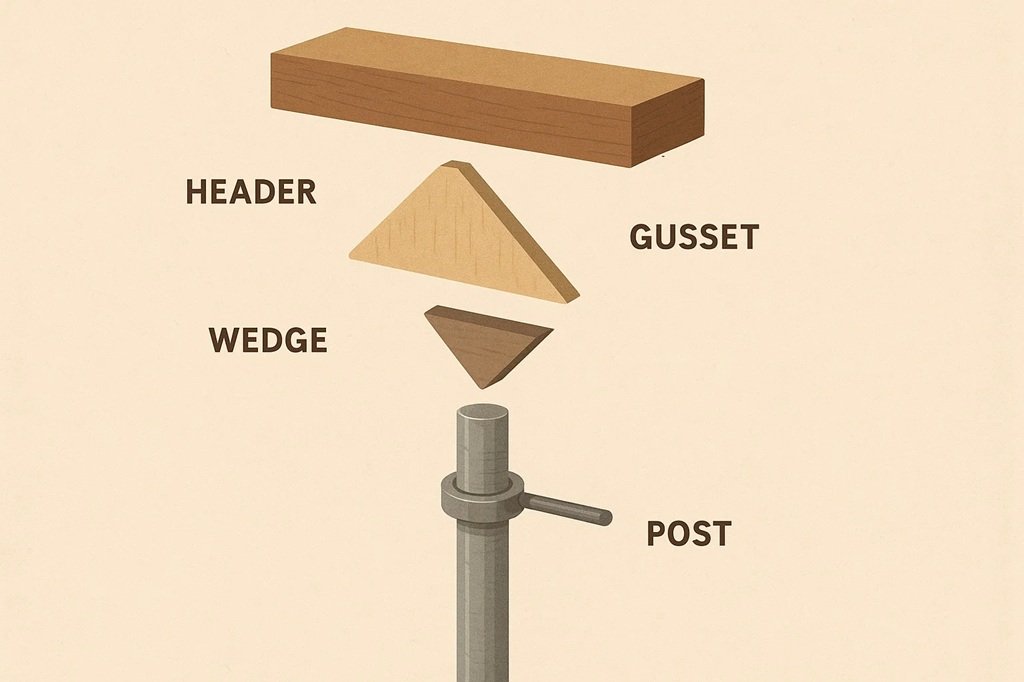

Shoring Components and Their Functions

Every shore comprises vital elements. Understanding these is critical for constructing safe, efficient systems:

| Component | Function |

|---|---|

| Sole Plate | Distributes load over the floor or ground |

| Header Beam | Collects and spreads the structural load |

| Post | Transfers load from header to sole plate |

| Diagonal Bracing | Stabilizes the structure against lateral movement |

| Gusset Plate | Secures joints and supports alignment |

| Cleat | Nails support components together |

| Wedges/Shims | Provides fine adjustment and compression |

Shoring in Excavation: Methods and Rules

Shoring for trench or excavation safety prevents wall collapse in deep or unstable dig sites.

Common methods:

Hydraulic Shoring – Uses aluminum hydraulic supports

Pneumatic Shoring – Air-powered bracing

Sheet Piling – Steel sheets driven into the ground

Soldier Pile and Lagging – Vertical beams with horizontal support

Important Note: Always refer to OSHA 1926 Subpart P for regulatory compliance.

Read our excavation rescue guide here →

Building a Vertical Shore: Step-by-Step How-To

Clear and level the area

Measure and cut the sole plate and header

Install the sole plate directly beneath load area

Cut and install vertical posts

Attach gussets and cleats

Tap wedges under posts to tighten

Secure wedges with nails

Install diagonal braces (X-pattern preferred)

Pro Tip Box

💡 Pro Insight: Always deduct the thickness of wedges before measuring posts this ensures snug fitting without overloading during installation.

Constructing a Window/Door Shore: Step-by-Step Guide

Clear opening area

Measure and cut sole plate and header

Set up wedges at sole and header levels

Cut and install side posts

Secure with cleats, gussets, and diagonal bracing

Note: If opening is to be used, avoid diagonal braces or install after rescue access.

Shoring Team Roles and Responsibilities

| Role | Function |

|---|---|

| Shoring Officer | Coordinates entire operation, decides shore placement |

| Measurer | Measures lumber sizes on-site |

| Cutting Team | Prepares materials per layout |

| Assembly Team | Installs the shore components |

| Safety Officer | Monitors hazards and ensures compliance |

| Runner | Transports tools, supplies, and cut lumber |

Learn how to organize a rapid deployment rescue team →

Common Tools and Equipment for Shoring

8d and 16d duplex nails

Hammer or pneumatic nailer

Circular saw

Tape measure

Level and plumb bob

Wedge sets

Gusset plywood

Lumber (10×10, 15×15, 20×20 cm)

Pro Tips for Safer and Stronger Shores

✅ Always brace shores against both vertical and lateral loads

✅ Use duplex nails for easy adjustment

✅ Keep posts within 30–60 cm of header edges

✅ Use X-bracing wherever possible

✅ Regularly inspect for movement or shifting

Training and Safety Guidelines for Shoring Crews

Practice rapid size-up and decision-making

Always deploy a Safety Officer

Use proper PPE: gloves, helmet, steel-toe boots

Conduct regular drills under time constraints

Stay updated with NFPA 1670 and FEMA USAR manuals

FAQs

What is the most common type of shoring?

The vertical shore is the most commonly used for supporting floors or ceilings.

What are the three types of shores?

The primary types include vertical shores, raker shores, and horizontal shores.

Is shoring necessary in every collapse?

Yes, whenever there’s a risk of secondary collapse or victim entrapment, shoring is essential.

Can you improvise shoring materials?

Yes, in resource-limited environments, bamboo, scrap wood, or metal pipes can be used.

How does excavation shoring differ from structural shoring?

Excavation shoring supports soil walls, while structural shoring supports built environments.

Conclusion & Actionable Resources

Understanding and applying shoring methods is a fundamental skill for emergency responders, firefighters, engineers, and safety officers. Whether saving lives from rubble or reinforcing an unstable wall during a rescue, the right method ensures safety, speed, and success.

Emma Lee, an expert in fire safety with years of firefighting and Rescuer experience, writes to educate on arescuer.com, sharing life-saving tips and insights.