When a disaster hits India floods in Assam, cloudbursts in Uttarakhand, cyclones on the eastern coast the first supply chain to collapse is clean water. Power fails. Groundwater turns murky. Storage tanks overflow with runoff. Relief camps fill up fast, and every team knows the rule: if drinking water isn’t safe, nothing else stays stable for long.

Here’s what matters.

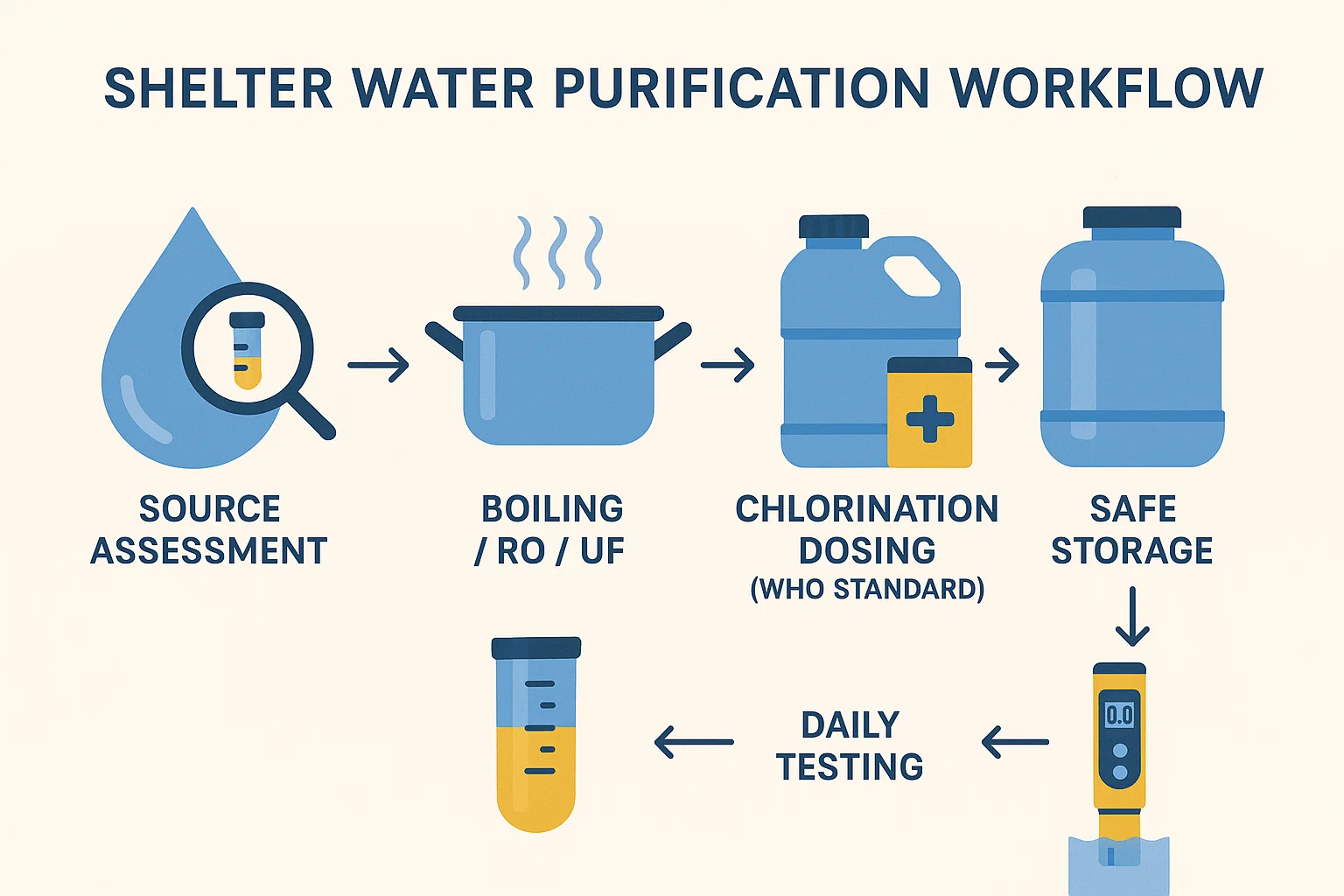

Shelters don’t fail because teams lack equipment; they fail because workflows break wrong dosing, dirty storage, untested water, or overconfidence in a single purification method. This guide focuses on the real work of keeping water safe inside camps, the kind of work responders in India handle day after day under pressure.

Let’s walk through a system that holds up in the field.

Why Water Becomes Unsafe During Indian Disasters

Most shelters receive water from one of these sources:

- Tankers arranged by district administration

- Borewells or handpumps already on-site

- Surface water (lakes, canals, floodwater runoff)

- Stored overhead tanks in schools or community buildings

- Private donations of packaged water

Now the friction.

During floods, nearly every low-lying source is contaminated. Sewers overflow. Agricultural chemicals mix with standing water. Turbidity shoots up. Borewells turn brown. Even stored water becomes unsafe because tanks aren’t cleaned before use.

Indian responders frequently run into:

- High turbidity (the water looks cloudy, even gritty)

- Fecal coliform contamination

- Chemical runoff after heavy rainfall

- Mosquito breeding in storage drums

- Recontamination because containers weren’t cleaned

- Camp volunteers dipping cups into tanks

So the job isn’t just purification it’s habit correction inside shelters.

Core Standards That Guide Safe Water in Indian Shelters

Here are the frameworks worth anchoring to:

- IS 10500:2012 Indian drinking water specification (revised parameters used in shelter testing).

- WHO Drinking-Water Guidelines (2024 update) clear limits for bacteria, chlorine residual, and turbidity.

- Sphere Handbook (WASH Standards) globally accepted humanitarian benchmark for shelters.

- NDMA Shelter Management Guidance India’s operational reference for relief camps.

A simple reminder from Sphere:

15 liters per person per day is the minimum for survival-level shelter operations.

When sizing purification systems, always work backward from population × 24-hour consumption.

The Field Approach: Start With Assessment, Not Equipment

Before treatment, every team should answer one question:

What exactly are we treating?

Use this quick four-point assessment when you reach a shelter:

- Source Type: tanker, borewell, stored tank, surface water

- Visibility: clear, slightly cloudy, muddy/turbid

- Odor: neutral, earthy, sewage-like, chemical

- Basic Field Test:

- turbidity tube

- chlorine residual test

- simple coliform presence/absence kit

- TDS (optional but helpful)

You can’t pick a treatment method until you know these four details.

Trying to chlorinate highly turbid water is one of the biggest operational mistakes in Indian camps. Chlorine becomes ineffective when water is too cloudy.

Best Purification Methods for Indian Disaster Shelters

1. Filtration (first line of control)

Filtration isn’t optional. It’s the foundation.

Good options for shelters:

- Cloth filtration emergency stopgap

- Candle/ceramic filters strong for community-level setups

- Gravity-based filters require no power

- Sand filtration units ideal for high-volume camps

- UF (ultrafiltration) units strong for pathogen removal

For very turbid water, run settling + sand filter before anything else.

UF units are popular with NDRF because they don’t rely on electricity and handle suspended solids well.

2. Boiling (the most reliable fallback)

If fuel is available, boiling is unbeatable.

Minimum rule:

Bring water to a rolling boil for one full minute.

In high-altitude Himalayan shelters:

Boil for three minutes because water reaches lower temperatures.

Use boiling for:

- Infants

- Pregnant women

- Elderly

- Immune-compromised shelter residents

But boiling alone doesn’t solve taste, sediment, or chemical contamination. Pair it with filtration when needed.

3. Chlorination (WHO-recommended)

Chlorine is one of the strongest tools Indian responders have if the dosing is correct.

Correct field dosing:

2–4 mg/L (ppm) free chlorine after 30 minutes contact time.

Target residual:

0.2–0.5 mg/L free chlorine at point of use.

Chlorination works best when:

- Turbidity < 5 NTU

- Water is visibly clear

- You have reliable test strips or a digital test kit

Never rely on visual judgment alone.

INDIA’S COMMON MISTAKE: adding “extra” chlorine for safety. Over-chlorination causes throat irritation, complaints, and mistrust among shelter residents.

4. Portable RO / UV / UF Units

NDMA, SDRF, and humanitarian NGOs often deploy these systems.

When RO is appropriate:

- Coastal regions with high salinity in groundwater

- Flooding caused saltwater ingress (common in Odisha, West Bengal)

- Borewell water with high TDS

When UF is appropriate:

- Camps with biological contamination

- Low-salinity water needing pathogen removal

- Power-limited areas

When UV is appropriate:

- Good-quality filtered water

- Low turbidity conditions

- Consistent power supply

Never use UV alone on cloudy or colored water.

5. Emergency Chemical Purification Kits

When responders arrive within hours of flooding, these kits matter:

- Chlorine tablets

- Aquatabs

- Bleach solution (prepared correctly)

- Iodine (rarely used and not long-term)

Bleach ratio reminder:

1% bleach = add 5 ml to 50 liters

5% bleach = add 1 ml to 50 liters

Always confirm the concentration printed on the bottle. India receives donations with varying concentrations, so never assume.

Safe Storage: The Silent Failure Point in Indian Shelters

Here’s the uncomfortable truth:

Shelters often purify water correctly but contaminate it during storage.

Fixable errors include:

- Using old oil drums or paint buckets (“cleaned” but unsafe)

- Open-top containers

- People dipping mugs directly

- Infrequent container cleaning

- Storing drinking water near wastewater drains

Golden rules for safe storage:

- Only food-grade blue drums or covered containers

- Tap-based dispensing never dipping

- Clean containers daily with bleach solution

- Keep water 30 feet away from toilets and drainage

Teach volunteers this simple rule:

If a hand touches the inside of a container, the container is no longer clean.

Daily Water Testing Protocol for Camps

Water testing shouldn’t wait for symptoms or complaints.

Do these checks twice a day:

- Chlorine residual level

- Smell and visual clarity

- Coliform presence (field kit) once per shift

- Turbidity using tube/turbidity strip

- Container cleanliness

If you get a positive coliform result, switch that camp’s supply to boiling + chlorination immediately and investigate the upstream cause.

Practical Camp Layout for Safe Water Distribution

A smart layout reduces risk more than any chemical.

Place water points:

- Away from latrines

- Close to cooking areas

- On raised ground to avoid runoff

- In shaded areas to slow chlorine evaporation

- With a clear queue lane to avoid crowding

One tap for every 250 people is a workable target based on Sphere minimums. More taps equal fewer hygiene problems.

Checklist for Indian Emergency Teams

(Use this in field briefings or shelter audits.)

- Identified: tanker / borewell / surface / stored

- Initial tests completed

- Turbidity acceptable for chosen method

Purification

- Filtration in place

- Correct chlorine dosing

- RO/UF/UV units installed where appropriate

- Boiling option available for at-risk groups

Storage

- Covered containers used only

- No dipping utensils

- Containers cleaned daily

- Taps functioning

Testing & Monitoring

- Chlorine residual checks twice daily

- Coliform tests every shift

- Logs maintained

Camp Layout

- Safe distance from toilets

- Water kept on raised area

- Queue system arranged

Field Tips From Real Operations

Here’s what tends to work when shelters are overwhelmed.

Tip 1 Build a “water team” from the camp residents

They handle distribution, cleaning, and crowd management.

This reduces recontamination dramatically.

Tip 2 Mark every container with the date and name of the person responsible

Accountability improves hygiene.

Tip 3 Install two parallel systems

One for cooking and drinking, another for washing.

This avoids overloading purification units.

Tip 4 Teach residents to smell for chlorine

People trust water more when they understand what “safe” smells like.

Tip 5 Put instructions in Hindi + regional language

Readability matters under stress.

Common Operational Failures and How to Prevent Them

Failure 1 Chlorine tablets tossed directly into large tanks

Fix: dissolve in a small bucket first, then mix into storage.

Failure 2 Trusting tanker water without testing

Fix: test every batch don’t assume contractor water is clean.

Failure 3 Assuming RO solves every problem

Fix: RO removes salts, not bacteria unless paired with UV or chlorination.

Failure 4 Recontamination during distribution

Fix: enforce tap-only rule and daily cleaning.

Failure 5 No documentation

Fix: maintain a simple board with daily chlorine values and water source notes.

Comparing Purification Methods for India Shelters

| Method | Strengths | Weaknesses | Best Use Case |

|---|---|---|---|

| Boiling | Highly reliable, kills pathogens | Fuel-heavy, time-consuming | High-risk groups; small shelters |

| Chlorination | Fast, cheap, scalable | Loses effectiveness in turbid water | Most relief camps, tanker water |

| UF Units | Good pathogen removal, low power needs | Slower for large volumes | Borewell water, rural shelters |

| RO Systems | Removes salts, metals, microbes | Needs power, maintenance | Coastal flooding, saline water |

| UV Systems | Great for clear water | Requires electricity, no residual protection | Schools, buildings with power |

| Sand/ceramic filtration | Handles turbidity well | Doesn’t kill pathogens alone | Pre-treatment stage |

Flood Relief Camp in Assam

A flood submerges three wards overnight. A school turns into a relief shelter hosting 480 residents. The borewell water is brown. Tanker water is arriving but untested.

A strong workflow would look like this:

- Assess: Turbidity high, faint odor → not fit for direct chlorination.

- Settle + sand filter the water.

- Chlorinate using correct dosing.

- Test: confirm 0.2–0.5 mg/L residual.

- Store in covered drums with taps.

- Monitor twice per day.

- Keep infants on boiled water only.

This simple six-step chain prevents 80% of common illnesses in camp settings.

Final Thoughts

Clean drinking water is not a luxury inside Indian disaster shelters; it’s the backbone of stability. When water is safe, illness drops, conflict decreases, and responders can focus on the real work of recovery. The methods aren’t complicated. The discipline is.

India’s emergency teams already work under intense pressure. A clear, repeatable system assessment → filtration → treatment → storage → testing keeps shelters functioning even in the toughest week after a disaster.

FAQs:

How much water should a shelter provide per person per day?

Aim for 15 liters per person per day, based on Sphere standards. More is ideal in hot regions.

Can tanker water be used without treatment?

No. Always test chlorine residual and turbidity. Tanker water often varies in quality.

What purification method works best during floods?

A mix of filtration + chlorination + boiling for vulnerable groups. UF units also hold up well.

What is the safest method for infants?

Boiled, cooled water only.

How often should water be tested in shelters?

Twice a day for chlorine residual. Once per shift for coliform presence.

Jordan Hayes, a rescue professional with years of hands-on experience, shares expert insights and tips to enhance safety and preparedness on arescuers.com