Why Turnout Gear Is More Than Just Uniform

Why Turnout Gear Is More Than Just Uniform

Every firefighter in Venezuela knows the weight of the ropa estructural not just in kilograms, but in responsibility. That heavy set of coat, trousers, boots, and hood isn’t mere attire; it’s the only barrier between you and thermal collapse. But what many don’t realize is that gear protection isn’t permanent. Heat, soot, and humidity slowly eat away at its protective layers.

In Venezuela, where tropical heat meets high fire intensity from urban Caracas to oil-sector emergencies in Maracaibo turnout gear faces accelerated degradation. Proper cleaning and decontamination (descontaminación) are no longer optional; they are the difference between protection and vulnerability.

Understanding the Thermal Protection System (TPS)

Turnout gear is built in three critical layers:

| Layer | Function | Common Materials | Key Risks When Damaged |

|---|---|---|---|

| Outer Shell | Flame resistance and abrasion protection | PBI, Kevlar, Nomex blends | Reduced flame resistance, tears |

| Moisture Barrier | Blocks water/steam, resists chemicals | PTFE or polyurethane membranes | Compromised waterproofing and chemical resistance |

| Thermal Liner | Insulates against radiant and conductive heat | Aramid batting and face cloth | Loss of insulation; higher burn risk |

Each layer performs only if maintained. Venezuelan humidity can cause delamination or mildew between layers, weakening the barrier system. INSAPSEL safety audits show that improperly dried gear loses up to 30% of its thermal resistance within two years.

The Heat Problem in Venezuela

Firefighters here often operate in ambient temperatures exceeding 32°C (90°F), with humidity over 70%. That combination doesn’t just make the work uncomfortable it changes how PPE performs. The moisture barrier absorbs more humidity, reducing breathability and increasing internal heat load.

A 2024 evaluation by the Cuerpo de Bomberos de Distrito Capital found that 53% of structural gear inspected failed moisture-barrier testing primarily due to improper drying and storage practices. Overheating, fainting, and early fatigue were common secondary outcomes.

That’s why Venezuelan brigades must adapt NFPA 1851 standards to local conditions simpler cleaning methods, field-adapted drying setups, and preventive inspection schedules tailored to high-humidity climates.

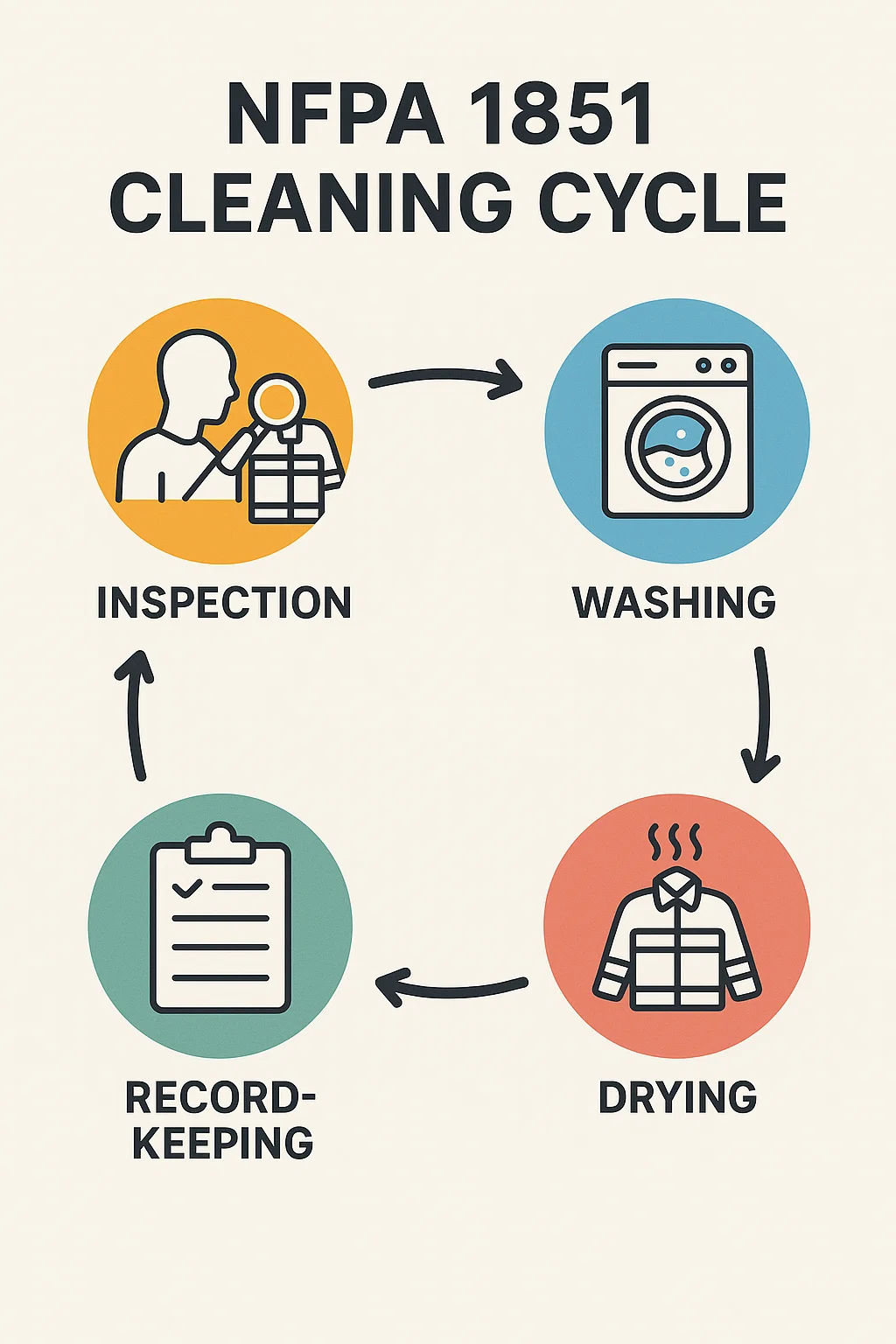

NFPA 1851 Meets Venezuelan Reality

NFPA 1851 defines PPE care, inspection, and decontamination. But Venezuela’s resource limitations scarce washing extractors, irregular detergent imports, and frequent power outages mean departments need adaptive, field-based solutions.

Here’s how the standard translates in practice:

| NFPA 1851 Requirement | Venezuelan Field Adaptation |

|---|---|

| Routine Inspection (After Each Use) | Visual check for discoloration, odor, delamination using portable light; report to safety officer. |

| Advanced Inspection (Every 12 Months) | Conducted at regional fire academy or municipal headquarters with UV lamp and hydrostatic test tools. |

| Routine Cleaning (After Every Exposure) | Use neutral detergent and clean water via manual soft-brush method in designated PPE zones. |

| Advanced Cleaning (Quarterly or Heavy Contamination) | Utilize industrial washers (if available) or external contractor under INSAPSEL supervision. |

| Record Keeping | Each garment logged in Registro de Equipo Individual per INSAPSEL guideline 2023/45. |

Step-by-Step: Field Cleaning and Decontamination

Even without industrial facilities, Venezuelan firefighters can safely clean turnout gear following a structured process:

1. Pre-Decon Preparation

- Move to a zona limpia (clean area) immediately after the incident.

- Remove SCBA before gear removal to avoid secondary contamination.

- Place contaminated items in sealed, labeled bags marked “POST-INCIDENT PPE”.

2. Gross Decon at Scene

- Use low-pressure water (<20 psi) and mild detergent to rinse soot, ash, and hydrocarbons.

- Never use high-pressure hoses they drive contaminants deeper.

- Brush gently with soft nylon tools (no wire brushes).

Pro Tip 💡:

Add a teaspoon of baking soda to every 5 liters of rinse water it neutralizes acidic residues from smoke particulates.

3. Routine Cleaning (Station Level)

- Submerge garments in lukewarm water (max 40°C) with approved NFPA detergent.

- Avoid bleach, softeners, or harsh solvents.

- Agitate gently by hand or use a front-load extractor if available.

- Perform two rinse cycles.

4. Drying

- Hang in a shaded, ventilated area never under direct sunlight.

- Avoid diesel heater rooms or clothes dryers over 105°F.

- Ensure airflow between layers using hanging spacers.

5. Post-Clean Inspection

Check for:

✅ Seam separation

✅ Color changes or odor

✅ Delamination bubbles

✅ Damaged reflective trim

If defects appear, mark as “OUT OF SERVICE” until re-certified by Técnico de Mantenimiento de PPE.

The Hidden Threat: Carcinogenic Residue

Fires in industrial or urban Venezuelan environments often involve plastics, fuels, and pesticides producing polycyclic aromatic hydrocarbons (PAHs), dioxins, and heavy metals. Studies by Universidad Central de Venezuela (UCV) show PAH levels in used turnout gear exceeding 3 mg/m² in some districts.

Even small residue exposure can cause chronic dermatitis or cancer risk. Therefore, every firefighter should treat PPE cleaning as personal health protection, not equipment maintenance.

Pro Tip 💡:

Store washed PPE separately from station sleeping quarters. PAHs can migrate through air and settle on bedding within hours.

Thermal Performance Testing in the Tropics

Because Venezuelan brigades lack NFPA-certified labs, basic thermal tests can be done locally:

Field Test Protocol:

- Place a clean gear sample 15 cm above a heat source at 150°C for 10 seconds.

- Observe any color change or smoke.

- Delamination or melted patches indicate thermal liner failure.

INSAPSEL recommends repeating this test quarterly for gear older than 3 years.

Extending PPE Life in High-Humidity Environments

Humidity accelerates microbial growth, degrading aramid fibers and stitching. Departments can slow this process with small environmental adjustments:

- Install passive drying racks with wall fans.

- Use silica gel packets in PPE lockers.

- Apply fabric-friendly antifungal spray quarterly.

- Rotate two sets of gear where budgets allow ropa de reemplazo.

These methods may sound basic, but according to the Bomberos del Municipio Sucre, dual-rotation extended PPE life expectancy by 18 months on average.

Safety Checklist Field PPE Cleaning Routine

| Step | Task | Responsible | Frequency |

|---|---|---|---|

| 1 | Visual inspection | Each firefighter | After every fire |

| 2 | Gross decon rinse | Crew team | On-scene |

| 3 | Routine cleaning | Station safety officer | Weekly or post-incident |

| 4 | Air drying | Designated PPE manager | Continuous |

| 5 | Record entry | Maintenance clerk | After drying |

Leadership Role in Gear Hygiene

Company officers set the tone. If the captain wears uncleaned gear, the crew follows. Departments must establish visible hygiene culture gear rooms marked by red/green zones (zona sucia / zona limpia), signage explaining contamination control, and mandatory cleaning logs.

Cuerpo de Bomberos del Estado Lara introduced color-coded PPE racks red for “to clean,” blue for “drying,” green for “ready” and saw a 40% reduction in contaminated gear within six months.

Addressing Common Myths in Venezuelan Stations

Myth 1: “Washing ruins the fabric.”

Truth: Neglect ruins it faster. Controlled washing removes soot that degrades fibers.

Myth 2: “Rain cleans it naturally.”

Truth: Rain contains acidic pollutants that weaken outer shells.

Myth 3: “Sun drying disinfects better.”

Truth: Direct UV exposure destroys reflective materials and moisture barriers.

Psychological & Health Impact

Beyond physical safety, clean PPE reduces mental stress. Many firefighters in Caracas report a sense of “relief and renewal” when wearing freshly cleaned gear symbolizing both hygiene and pride. INSAPSEL’s 2023 survey linked regular decon habits with a 21% decrease in reported respiratory irritation among municipal brigades.

Integrating Technology and Future Trends

The Venezuelan fire service is slowly adopting technology-driven maintenance:

- Ozone Decontamination Cabinets: Decompose organic residues without water ideal for smaller stations.

- RFID Gear Tracking: Some Caracas stations are tagging PPE for digital record-keeping in line with NFPA 1851.

- Portable Decon Units: Lightweight sprayers for rural brigades working far from infrastructure.

These upgrades align with a national effort under Plan Nacional de Prevención y Atención de Desastres 2025–2030 to modernize firefighter safety systems.

Case Study: Maracaibo Refinery Incident (2024)

After a large petroleum fire in 2024, Bomberos de Maracaibo implemented rapid decon stations using portable pumps, detergent sprayers, and shade tents. Testing post-incident showed a 60% reduction in surface hydrocarbons on PPE and zero reported skin burns.

Their approach improvised yet disciplined has since been replicated across five Venezuelan states.

Table Common Cleaning Mistakes & Safer Alternatives

| Mistake | Result | Corrective Action |

|---|---|---|

| Using bleach or gasoline for cleaning | Fiber degradation, fire risk | Use neutral pH detergent approved for aramid fabric |

| Machine spin at high RPM | Stitching failure | Use gentle/manual agitation only |

| Storing gear in vehicles overnight | Moisture buildup, mildew | Air dry and ventilate |

| Wearing soiled gear to training | Cross-contamination | Maintain separate sets |

| Using domestic detergents | Chemical reaction with barrier | Purchase NFPA-certified or mild baby detergent alternatives |

Building a Sustainable Decon Culture

Creating a “clean gear” culture requires leadership, budget alignment, and awareness. Departments can begin small:

- Designate PPE hygiene officers.

- Integrate decon into training drills.

- Secure partnerships with universities for residue testing.

- Educate families many firefighters take contaminated gear home unknowingly.

Pro Tip 💡:

INSAPSEL offers short courses on “Manejo y Descontaminación de Equipos de Protección Personal.” Sending just one crew member can create internal trainers for years.

Venezuelan PPE Future Outlook

Local manufacturers like Seguridad Industrial Andina C.A. and ProtecFire Venezuela are developing turnout gear using lighter aramid blends suited to high heat. Combined with national regulation harmonization under Norma Técnica Venezolana (NTV) 2025, this signals progress toward self-reliance in PPE production and maintenance capability.

Firefighters must continue adapting combining modern science with local ingenuity to keep every call safe.

✅ Quick PPE Cleaning Checklist (for posting in stations)

After Each Fire:

- Rinse gear with low-pressure water and mild detergent.

- Remove liners, rinse separately.

- Air dry in shaded area.

- Record cleaning in PPE log.

- Inspect reflective trims and seams.

Weekly:

- Conduct visual inspection under bright light.

- Reapply antifungal spray if humidity >70%.

- Rotate storage sets.

Quarterly:

- Perform heat liner check.

- Replace damaged closures.

- Submit report to PPE officer for record certification.

Frequently Asked Questions (FAQ)

Q1: How often should Venezuelan firefighters wash turnout gear?

After every fire or exposure, and at least monthly per INSAPSEL’s recommendation, aligning with NFPA 1851.

Q2: Can regular detergents be used?

No. Domestic detergents often contain softeners and optical brighteners that weaken aramid fibers.

Q3: What’s the safe drying temperature for PPE?

Below 105°F (40°C). Direct heat or sun can warp reflective tape and moisture barriers.

Q4: How do you check for delamination?

Press between thumb and forefinger if air bubbles move or the surface feels uneven, liner separation has started.

Q5: Is decon required for all fires?

Yes even small kitchen or vehicle fires release toxic residues that adhere to fabrics.

Final Thoughts Protect the Protector

Every call in Venezuela tells the same story: courage meets chaos. But that courage must wear protection that works. The best turnout gear can fail if not maintained; the simplest cleaning habit can save a life years later.

Thermal protection isn’t eternal it’s earned every time you clean, inspect, and respect the gear that guards your body.

In a humid, demanding land like Venezuela, the battle for safety begins not at the fire scene but in the wash bay.

Emma Lee, an expert in fire safety with years of firefighting and Rescuer experience, writes to educate on arescuer.com, sharing life-saving tips and insights.