In today’s Ukraine, chemical storage is more than an industrial concern it’s a national safety priority. Factories, logistics hubs, and emergency responders now manage volatile substances under wartime conditions, damaged supply chains, and shifting European Union regulations. Getting storage safety right means protecting both lives and the country’s recovery.

This field guide lays out proven, NFPA- and EU-aligned tactics for keeping chemical facilities secure, minimizing fire potential, and protecting response crews on the ground.

The Reality on the Ground

Across central and eastern Ukraine, hundreds of chemical warehouses still rely on pre-2010 infrastructure concrete shells, weak ventilation, and unsealed drainage systems. The State Emergency Service (ДСНС) has warned of multiple fire incidents linked to poor segregation and reactive chemical mixing.

Yet progress is visible: EU integration efforts now require sites handling more than 10 tonnes of dangerous substances to comply with the Seveso III Directive (2012/18/EU). That directive focuses on preventing major-accident hazards and ensuring transparent reporting of chemical inventories.

For fire officers and safety engineers, it means one mission: adopt layered defense design, training, and readiness to stop a leak or ignition from becoming an industrial disaster.

Understanding the Hazard Landscape

Commonly Stored Chemicals in Ukraine

| Chemical Type | Industrial Use | Main Fire/Explosion Hazard | Storage Control |

|---|---|---|---|

| Flammable Liquids (acetone, ethanol, toluene) | Paints, pharma, cleaning agents | Vapour ignition at 12–30 °C | Temperature-controlled rooms, explosion-proof lighting |

| Oxidizers (hydrogen peroxide, nitrates) | Fertilizers, disinfectants | Accelerate combustion | Non-combustible shelving, distance from fuels |

| Corrosives (sulfuric acid, caustic soda) | Battery production, water treatment | Violent reaction with metals/water | Acid-resistant flooring, neutralization kits |

| Compressed Gases (oxygen, LPG) | Welding, hospitals | BLEVE risk if overheated | Cylinder restraint & ventilation |

| Toxic Chemicals (ammonia, chlorine) | Refrigeration, purification | Poisonous vapor cloud | Leak detection & scrubber systems |

Pro Tip 1: Always cross-reference the NFPA 704 Diamond and the EU CLP (GHS) labeling mismatched hazard codes are a leading cause of storage mix-ups in imported stock.

Building a Safe Storage System

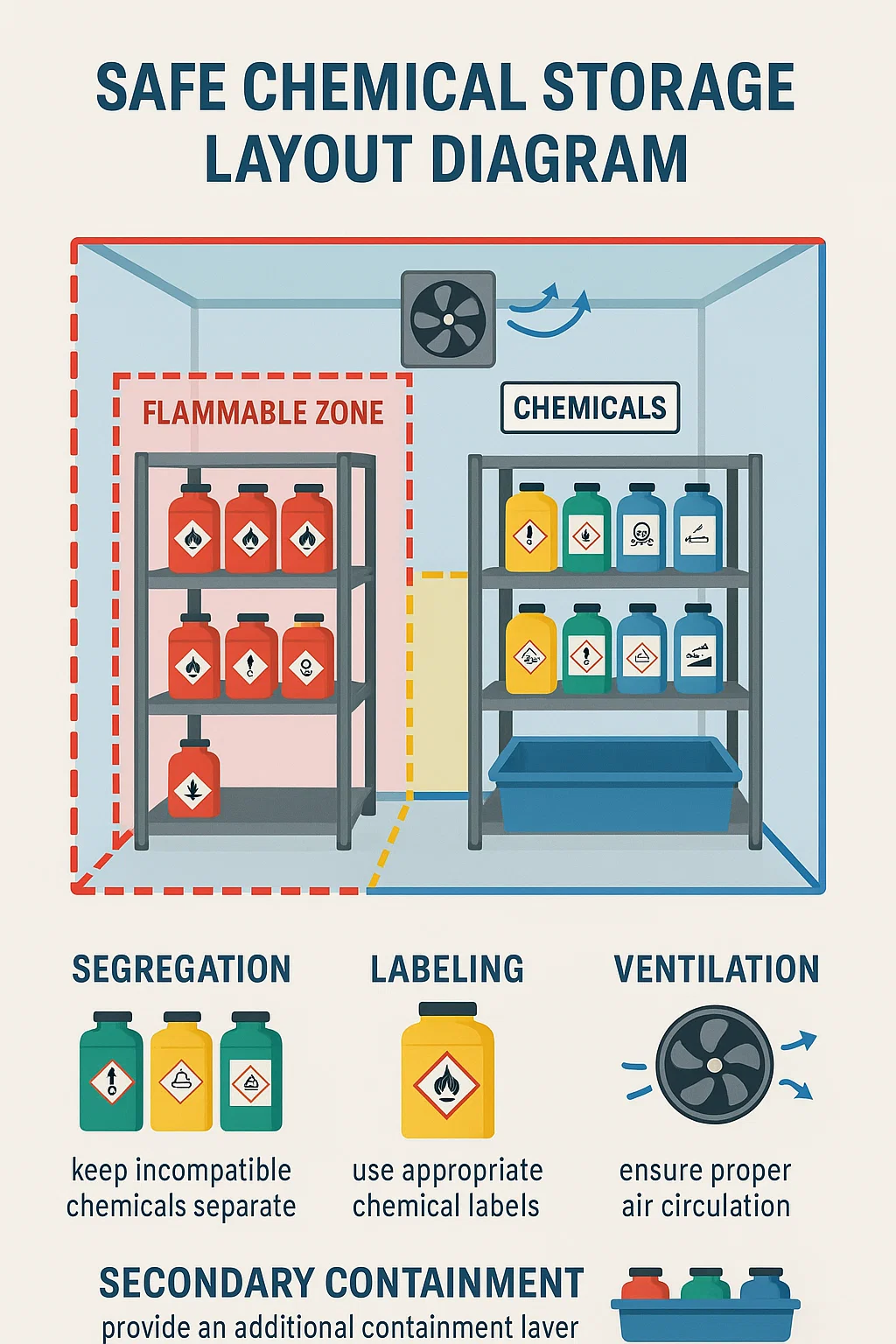

Segregation and Compatibility

Never store incompatible classes together. EU Annex I of the Seveso III Directive defines threshold quantities and incompatibility groups. Use color-coded floor markings blue for corrosives, red for flammables, yellow for oxidizers to make incompatibility visible to every responder.

Checklist Daily Visual Inspection

- ✅ Confirm chemical labeling in both Ukrainian and English per GHS.

- ✅ Check secondary containment for cracks or overfill.

- ✅ Verify aisle clearance ≥ 1 m.

- ✅ Inspect fire-rated doors & automatic closers.

- ✅ Record temperature & ventilation readings.

Containment and Drainage

- Secondary containment must hold 110 % of the largest vessel’s capacity.

- Spill channels should direct flow toward neutralization basins, never outside drains.

- Bund walls should be acid-resistant concrete, 300 mm high minimum.

Engineering Controls: Ventilation, Sensors, and Barriers

Ventilation

Per OSHA 1910.1450 and NFPA 30, provide 6–10 air changes/hour in flammable-liquid rooms.

Use ATEX-rated fans to prevent spark ignition.

For toxic vapors, install local exhaust hoods at drum-opening points.

Sensors and Early Warning

- Gas detectors (ammonia, chlorine) linked to visual/audible alarms.

- Thermal cameras for over-temperature drums.

- Automatic sprinkler activation sensors integrated into SCADA panels.

Barriers and Zoning

EU guidelines specify three storage zones:

- High-hazard (inner) – limited access, automatic suppression.

- Moderate-hazard (buffer) – forklift and loading areas.

- Administrative (outer) – offices, records, muster points.

Fire-Prevention Measures

Passive Protection

- Fire-rated walls ≥ 2 hours per EN 13501-2.

- Flame-retardant coatings on steel structures.

- Explosion-relief panels on roof sections of solvent rooms.

Active Protection

- Automatic sprinklers designed per NFPA 13, density 0.30 gpm/ft² for Class IIIB liquids.

- Foam systems (AFFF 3 %) for hydrocarbon areas.

- Dry-chemical extinguishers rated 80-B for small flammable-liquid rooms.

- Remote isolation valves for LPG pipelines.

Pro Tip 2: If water supply is unreliable, integrate portable bladder-tank foam units they provide 60 seconds of response when the main system fails.

Personal Protective Equipment (PPE)

| Task | Minimum PPE | Notes |

|---|---|---|

| Drum handling | Chemical-resistant gloves (EN 374), splash goggles | Avoid nitrile gloves with ketones |

| Spill response | Level B suit + SCBA | Minimum 30 min air supply |

| Fire suppression | Structural turnout + SCBA + Nomex hood | Ensure anti-static boots |

| Cleanup & neutralization | APR respirator + face shield + Tychem suit | Replace cartridges after each operation |

Keep PPE rotation logs. Damaged gloves or seals often cause unseen chemical burns hours later.

Emergency Response Integration

Incident Command Alignment

Under Seveso III, each major facility must maintain an Internal Emergency Plan (IEP) coordinated with municipal External Plans (EEP).

Ukraine’s transition to EU alignment encourages integration with ICS (Level 3) structure:

- IC – Incident Commander: facility or local fire officer.

- Safety Officer: monitors exposure & PPE compliance.

- Operations Chief: spill containment & ventilation.

- Planning Chief: resource tracking, site maps.

- Logistics Chief: foam replenishment, SCBA maintenance.

Communication Protocols

- Use UHF radios (450–470 MHz) with designated “HazMat” channel.

- Pre-load translation cue cards (Ukrainian ↔ English ↔ Polish) for cross-border response teams.

- Integrate weather API data for plume-model projections.

Decontamination

Set up three zones:

- Hot Zone: incident core.

- Warm Zone: decon operations.

- Cold Zone: support & medical.

Use neutralizing agents (soda ash for acids, boric acid for alkalis). Drain to sealed tanks only.

Training and Drills

Quarterly drills are mandatory under Seveso III Annex IV.

Each session must include:

- Simulated leak with evacuation.

- PPE donning & doffing.

- Foam system activation test.

- Decontamination line setup.

- Post-incident debrief.

Use table-top exercises for new supervisors and live drills for operations crews.

Record completion in site logs auditors will request them.

Documentation and Compliance

Required Records

- Chemical inventory & Safety Data Sheets (SDS) updated monthly.

- Maintenance log for ventilation & sensors.

- Fire-extinguisher inspection tags.

- Worker training attendance.

Reporting Obligations

Under Seveso III Article 13, facilities must notify local authorities of any incident causing death, injury, or environmental contamination.

Submit within 48 hours, with root-cause analysis in 14 days.

Auditing

Adopt ISO 45001:2018 (Occupational Health & Safety Management) as a baseline.

Independent audits every 2 years help align Ukrainian firms with EU expectations and attract insurance coverage.

Learning from European Incidents

- Toulouse, France (2001) – Ammonium nitrate explosion; led to Seveso II reform.

- Czech Republic (2015) – Paint factory fire; sprinklers inoperable due to corrosion.

- Poland (2023) – Illegal chemical dump ignited; lack of inventory data slowed response.

Each case reinforced the same lesson: accurate labeling, robust containment, and pre-incident coordination save lives.

The Human Factor

Even the best system fails if workers treat safety as paperwork.

Build culture through:

- Visible leadership managers wearing PPE.

- Reward programs for incident reporting.

- Open briefings before hazardous transfers.

- Peer mentorship between new and senior fire officers.

A study by the European Agency for Safety and Health at Work (2024) showed that plants with monthly safety walks reduced chemical fire incidents by 38 %.

Cross-Border Cooperation

Ukraine’s EU candidate status encourages interoperability with neighbors under the Union Civil Protection Mechanism (UCPM).

Shared tactics include:

- Exchange of Seveso incident data.

- Joint training with Poland and Slovakia.

- Harmonized PPE standards per EN 469 and EN 14605.

These efforts mean Ukrainian responders can integrate seamlessly into multinational HazMat deployments.

Future Outlook

Emerging tools:

- AI-driven risk prediction analyzing sensor data for early leak detection.

- Drone-based thermal mapping of large tank farms.

- Green chemistry substitutions reducing flammable solvent use.

- Smart labels (RFID + QR) for instant hazard ID via mobile app.

Ukraine’s movement toward EU membership will accelerate adoption of these technologies turning compliance from burden into innovation.

Field Summary

Chemical safety isn’t paperwork it’s protection.

By aligning Ukraine’s industrial sites with NFPA and Seveso III standards, responders gain predictability, visibility, and control in the most chaotic moments.

Every label, sensor, and training drill adds another layer of defense between a minor spill and a catastrophe.

FAQ

Q1. What is the Seveso III Directive and why does it matter in Ukraine?

A: It’s the EU law (2012/18/EU) governing prevention and control of major-accident hazards involving dangerous substances. Ukraine’s alignment ensures safer industrial operations and EU trade compatibility.

Q2. How often should chemical-storage drills be held?

A: At least quarterly, with one live drill per year to test real foam systems and ICS coordination.

Q3. Which standards regulate chemical-storage fire protection?

A: Key references include NFPA 400, NFPA 30, EN 13501-2 (fire resistance), and OSHA 1910.1450 (laboratory safety).

Q4. What is the minimum secondary containment volume?

A: EU best practice requires 110 % of the largest container volume or 25 % of total inventory, whichever is greater.

Q5. What PPE should responders use for toxic leaks?

A: Level B ensemble with SCBA and chemical-resistant gloves (EN 374), plus decontamination before exit from the warm zone.

Emma Lee, an expert in fire safety with years of firefighting and Rescuer experience, writes to educate on arescuer.com, sharing life-saving tips and insights.